Description

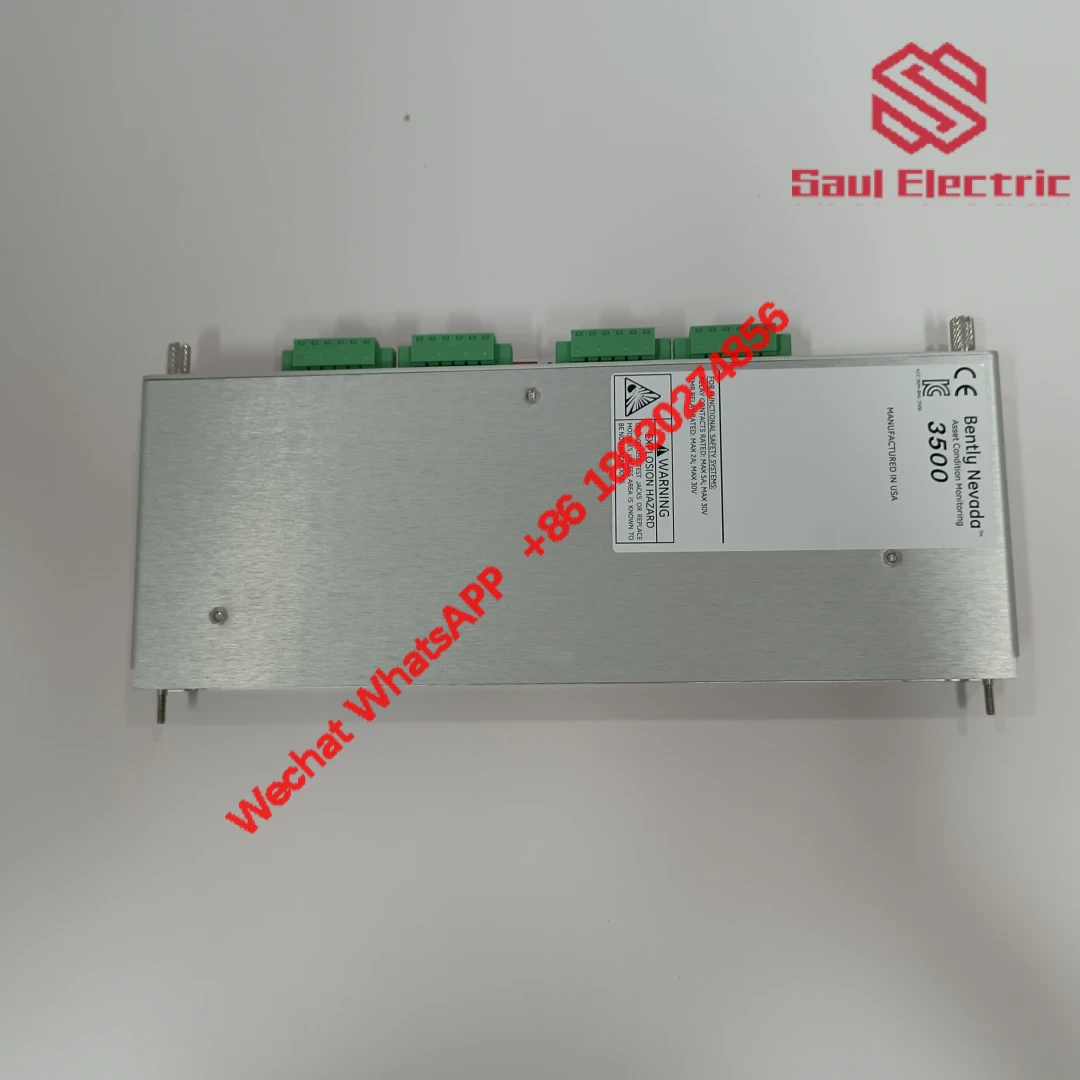

BENTLY 125720-01 Vibration Monitoring Module

Engineered for precision diagnostics in demanding industrial environments, the BENTLY 125720-01 Vibration Monitoring Module delivers continuous vibration analysis to prevent catastrophic machinery failures. Its primary role involves capturing high-frequency vibration data from rotating equipment like turbines, compressors, and pumps, enabling maintenance teams to detect early signs of imbalance or misalignment.

| Specification | Details |

|---|---|

| Brand | BENTLY NEVADA |

| Model Number | 125720-01 |

| Operating Voltage | 220 V AC |

| Output Frequency Range | 0-30 kHz |

| Certifications | CE, UL, ATEX |

Commonly deployed in oil & gas pipelines, power generation facilities, and chemical processing plants, this module integrates seamlessly with BENTLY’s 3500/3300 system architectures. For instance, when paired with 3500/44 relay modules or 3500/22M velocity sensors, it forms a comprehensive protection network for critical turbomachinery. Our inventory frequently handles related components like 3500/323500/15 and 3500/203500/42M units, ensuring system-wide compatibility for retrofitting or expansion projects.

What sets this module apart is its dual-channel redundancy design, allowing uninterrupted monitoring even during component failure. The built-in signal conditioning circuitry maintains ±0.5% measurement accuracy across extreme temperature fluctuations (typically -40°C to +75°C operational range). Unlike standard vibration sensors, its 24-bit data acquisition provides sub-micron resolution, crucial for detecting subtle bearing wear patterns in early failure stages. Engineers we’ve spoken to particularly appreciate its compatibility with both legacy 1900-series systems and modern Proximitor probe arrays, eliminating the need for costly system overhauls during upgrades.

Reviews

There are no reviews yet.