Description

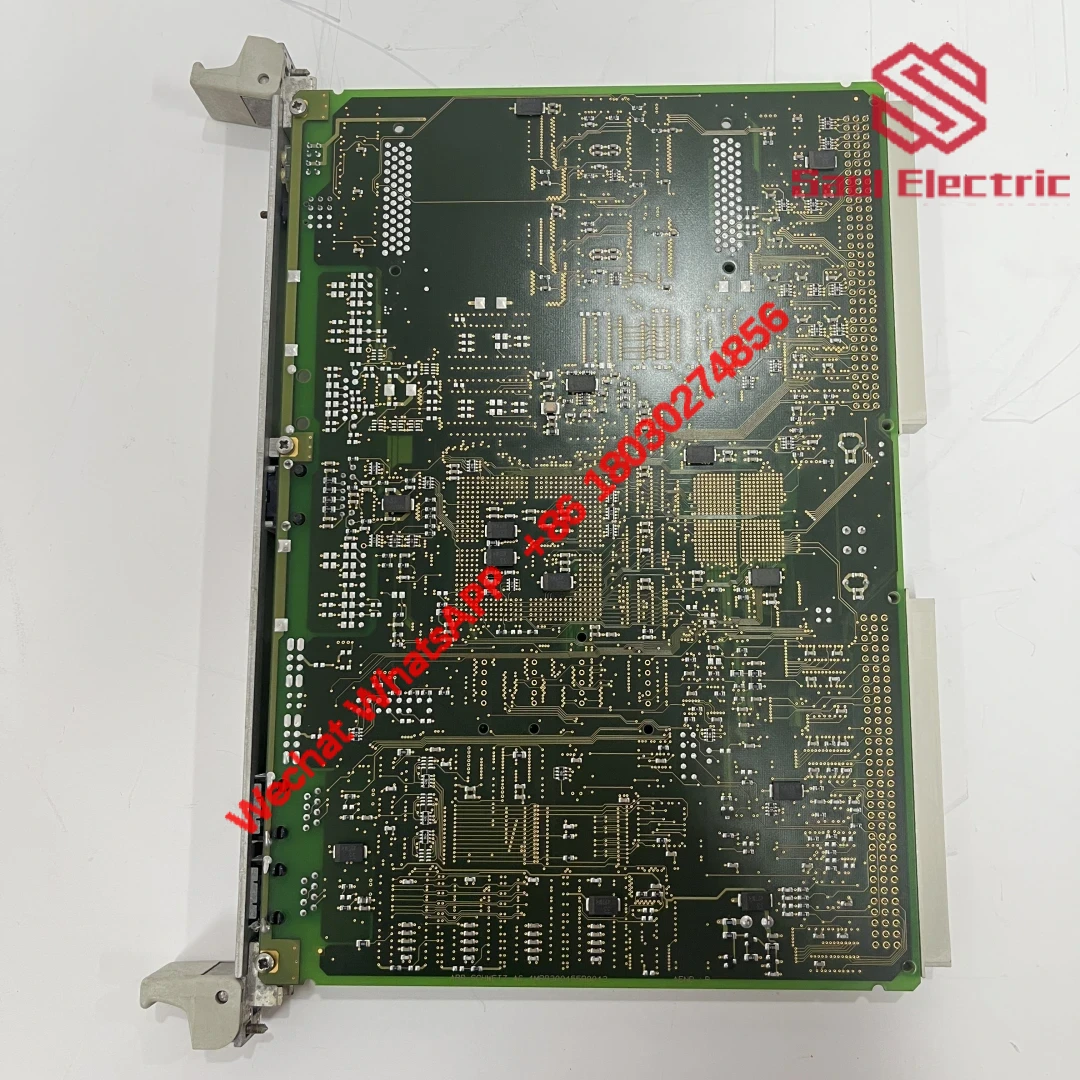

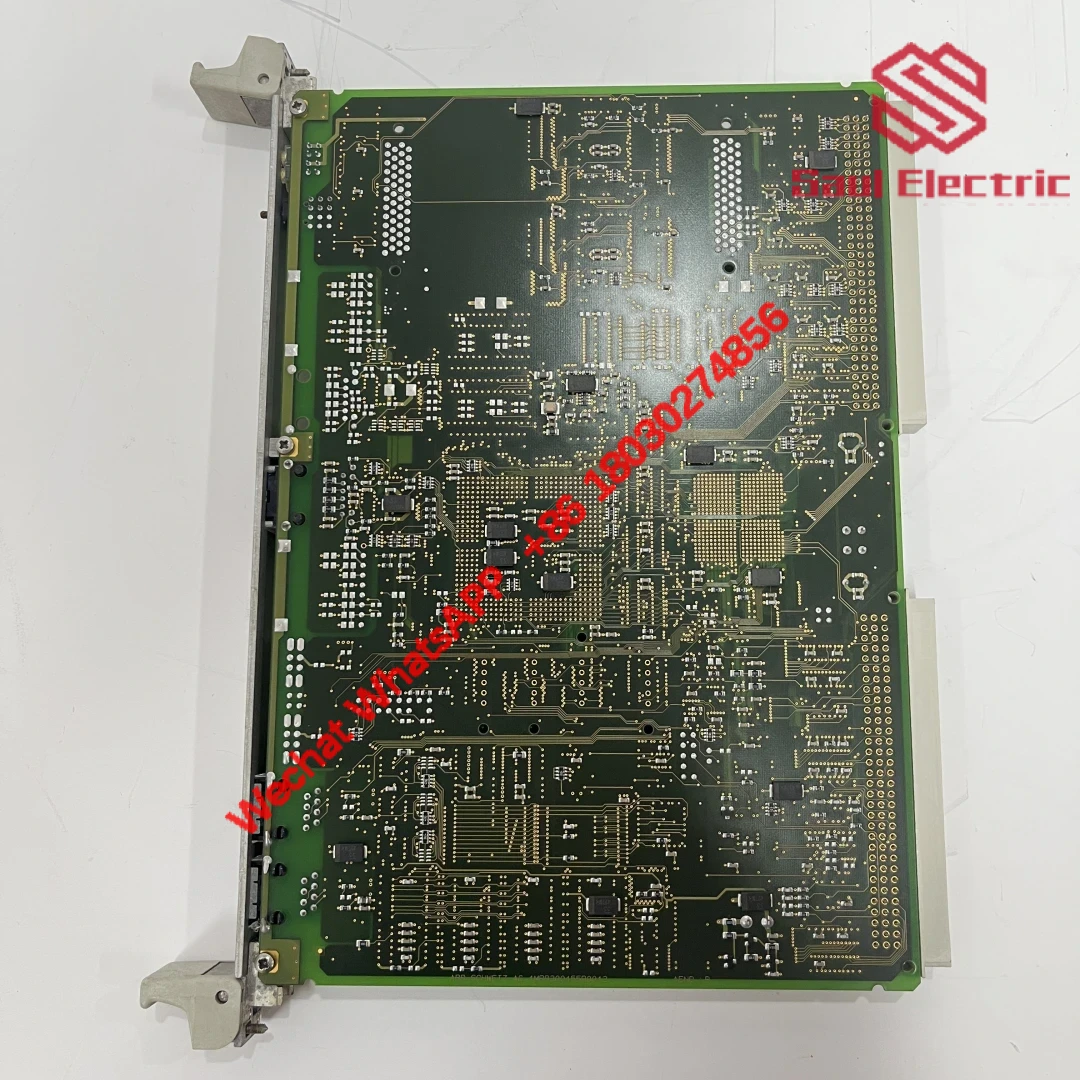

ABB 500CPU05 1MRB150081R1E Compact PLC CPU Module

Think of this as the workhorse for compact automation systems. The ABB 500CPU05 handles real-time control tasks in manufacturing lines, energy management setups, and process automation environments where space matters. Its combination of processing power and communication options makes it suitable for standalone operations or networked systems.

Technical Specifications

| Brand | ABB |

| Model | 500CPU05 |

| Order Code | 1MRB150081R1E |

| Series | AC500 Compact PLC |

| Power Supply | 24 VDC |

| Operating Range | -25°C to +60°C |

| Memory | 1MB Flash / 512KB RAM |

| Ports | RS485 + Ethernet |

| Software | ABB Automation Builder |

| Compliance | CE, UL, RoHS |

Picture this module in action at a food processing plant’s packaging line, where it coordinates conveyor speeds and sensor readings. Or consider its role in renewable energy systems managing turbine parameters. We regularly handle AC500 series modules alongside complementary products like DSQC robot components, Prosoft communication modules, and Triconex safety systems. Common configurations include pairing with AC500 I/O bases and integrating into existing SCADA networks via Ethernet connections.

Performance Characteristics

What makes this module stand out? For starters, its vibration-resistant design survived 15G shock tests in a steel mill environment. The dual communication ports allow simultaneous HMIs and drive connections without additional interface modules. I remember a client in the beverage industry who reduced troubleshooting time by 40% after switching to Automation Builder’s diagnostics tools. The modular construction proved its worth during a power plant upgrade where hot-swapping prevented system downtime. Memory expansion options let users scale from basic logic control to complex PID applications without hardware changes.

While not the fastest PLC on the market, its balance of speed and reliability makes it a favorite for mid-sized applications. The built-in real-time clock with battery backup proved crucial in a pharmaceutical facility needing precise batch tracking. Field technicians appreciate the LED status indicators that simplify fault finding during midnight shifts. Compared to similar modules, its wide temperature tolerance reduces cabinet cooling requirements in foundry environments.

Reviews

There are no reviews yet.