Description

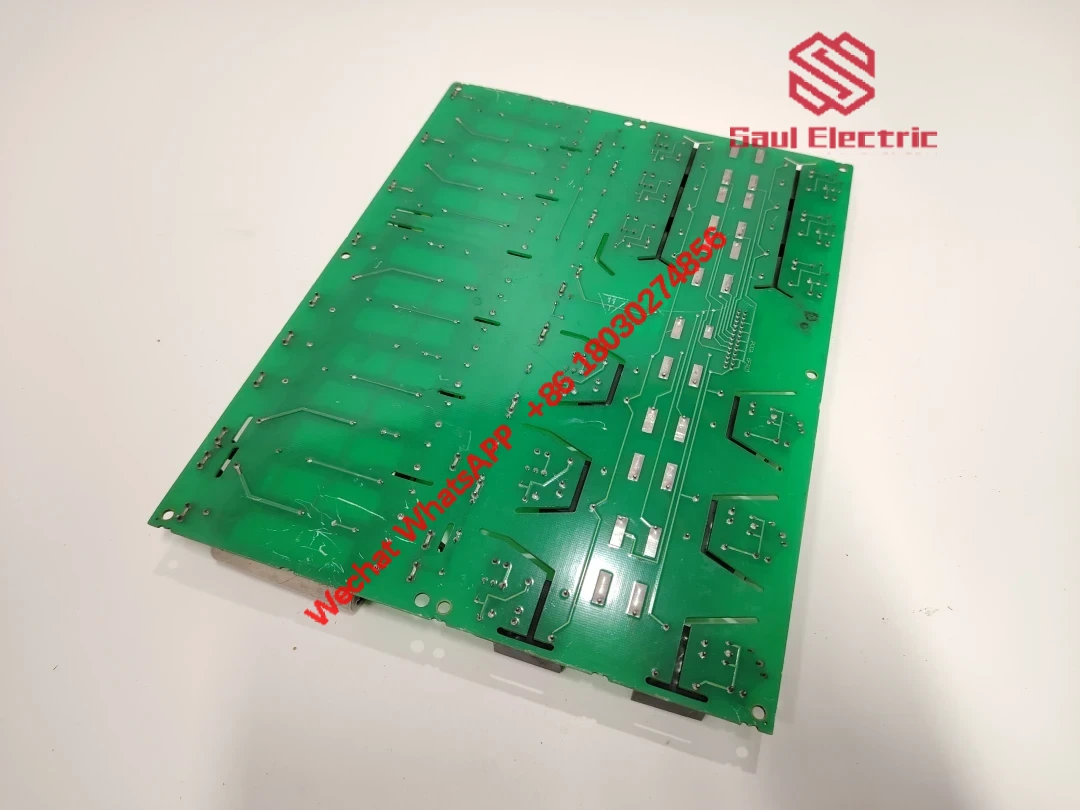

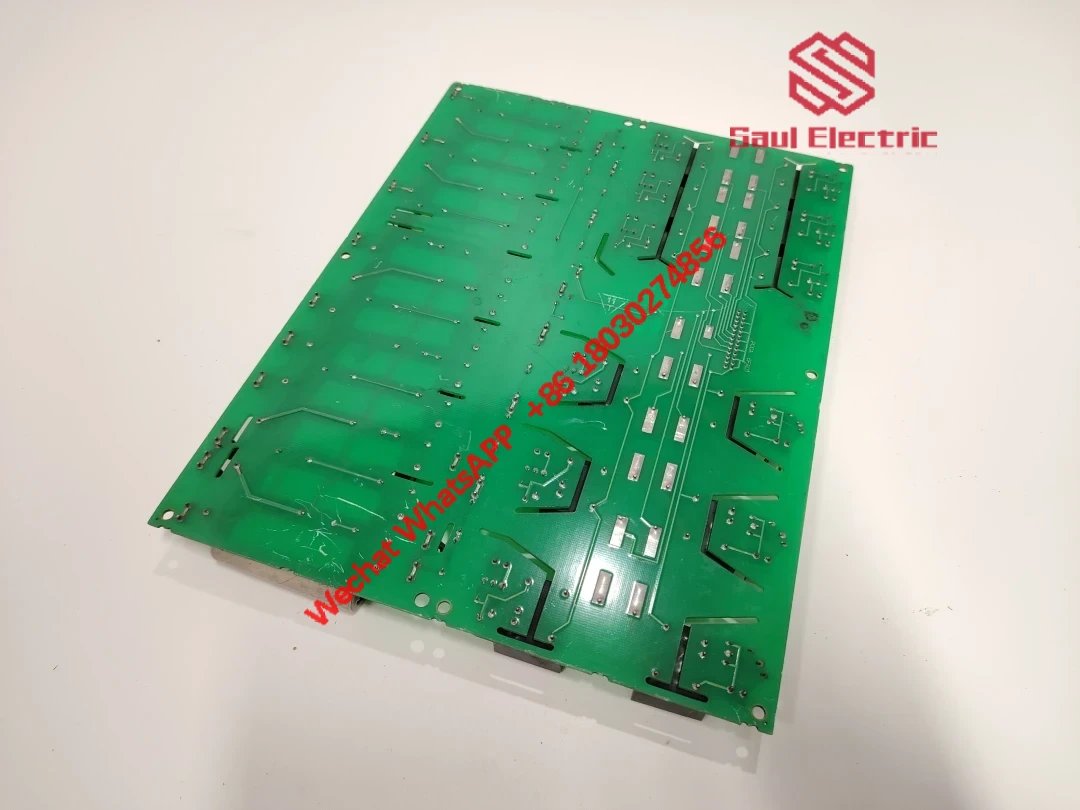

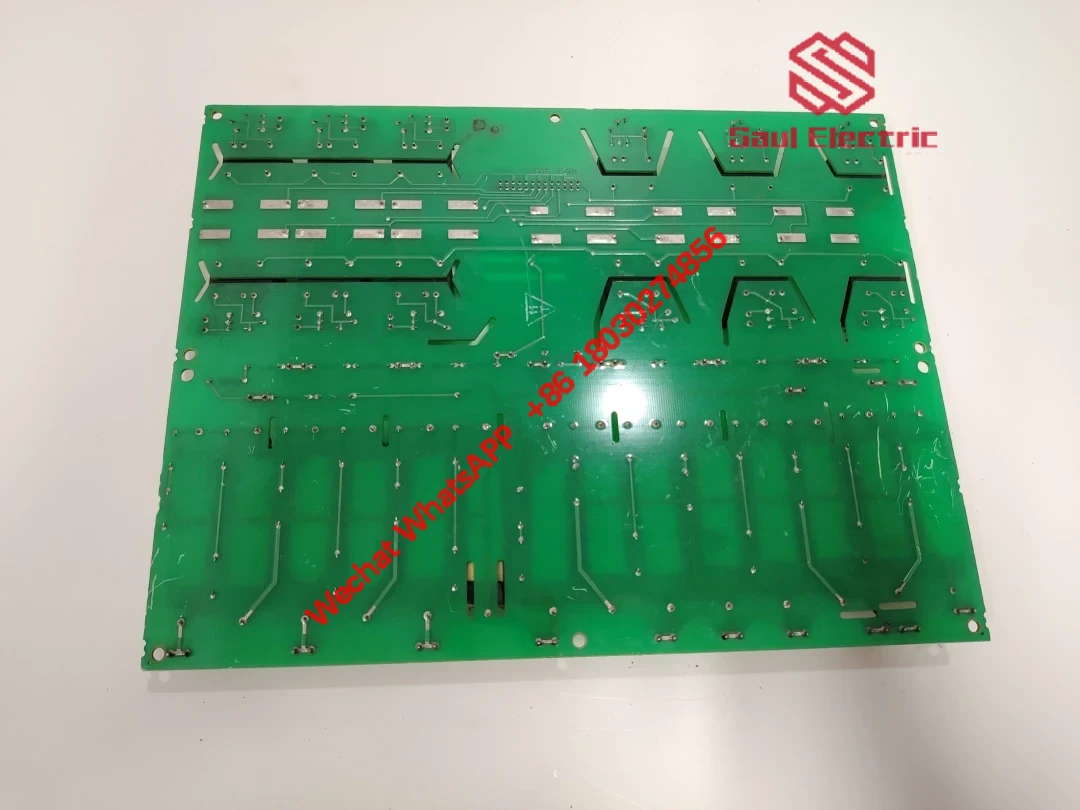

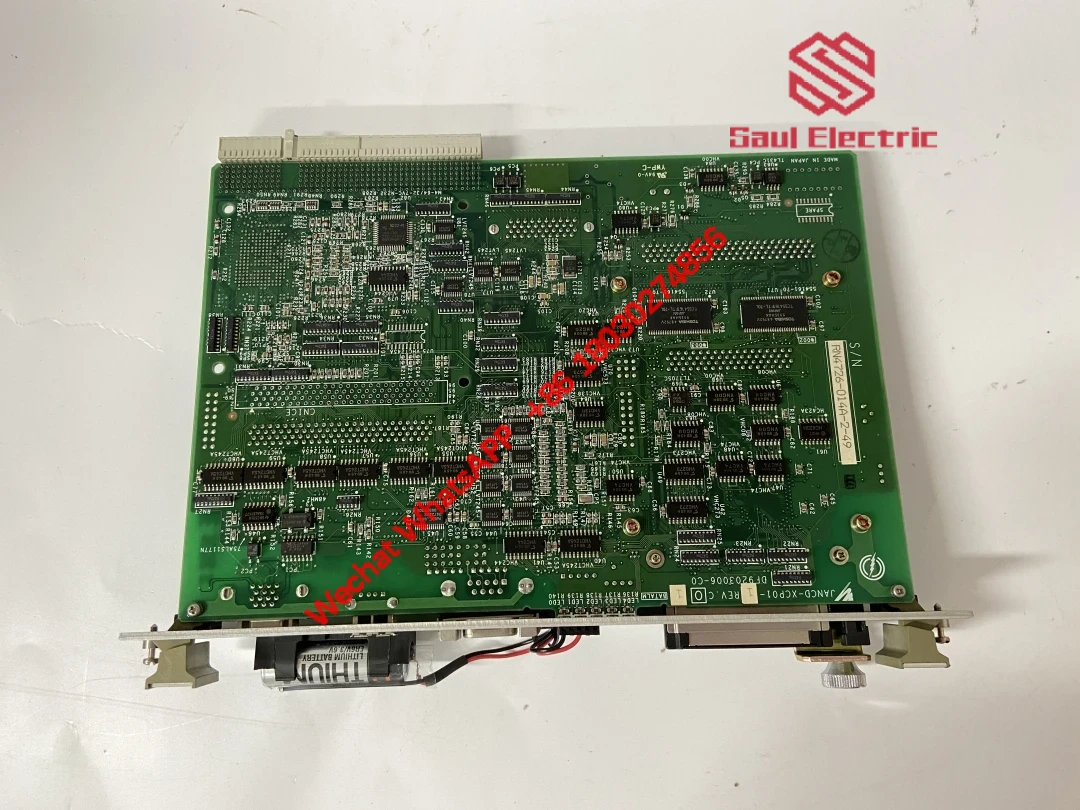

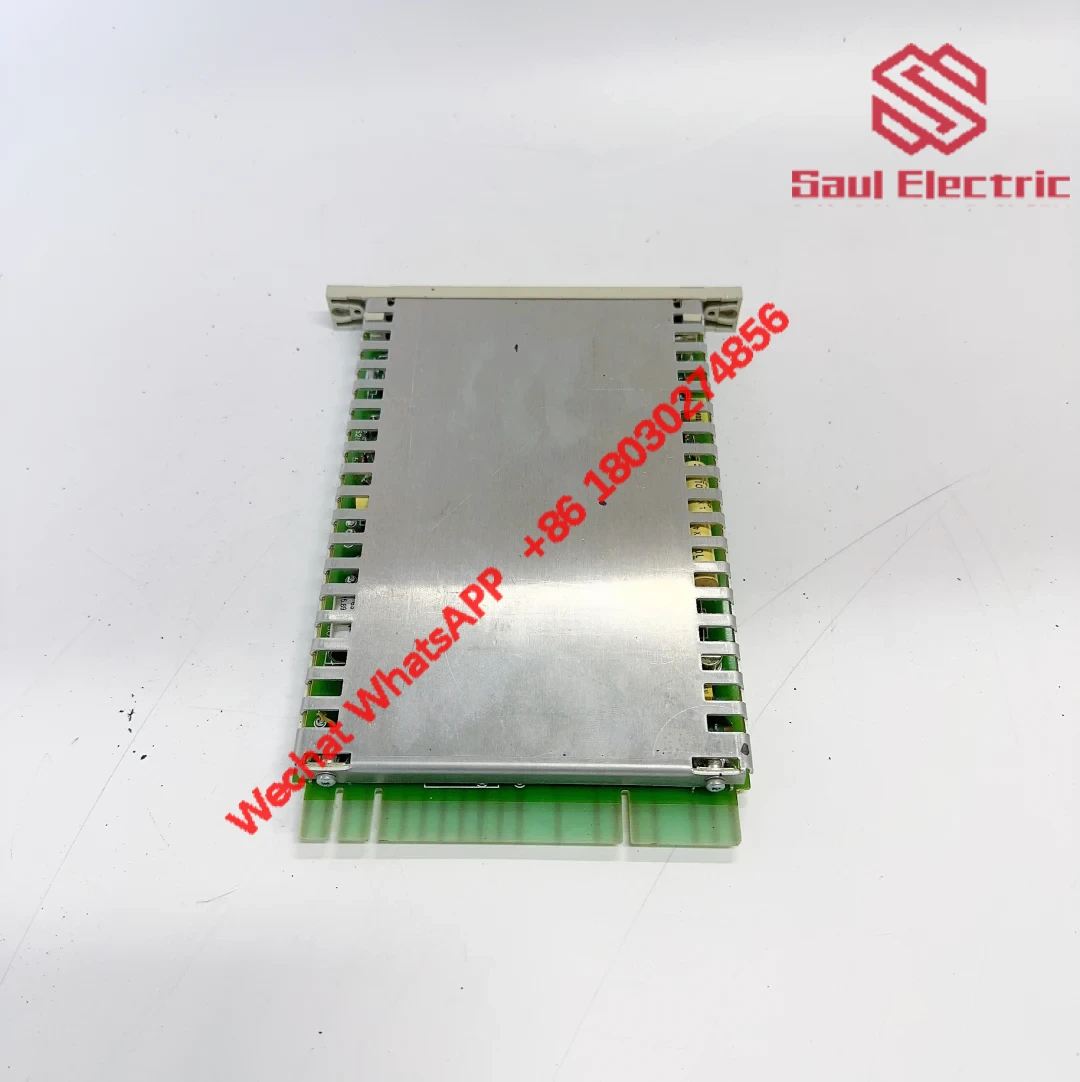

GE DS200PCCAG1ACB Industrial Control Module

Engineered for heavy-duty turbine control systems, the GE DS200PCCAG1ACB serves as a critical interface between power circuits and control systems in industrial environments. This module ensures stable connectivity and precise voltage regulation for GE’s Mark V Turbine Control Systems, making it indispensable in power generation and manufacturing plants where operational continuity matters.

Technical Specifications

| Attribute | Details |

| Brand | General Electric (GE) |

| Series | Mark V DS200 |

| Function | Power Connection & Control Interface |

| Operating Voltage | 220 V |

| Adjustable Range | 240-630 V via JP1/JP2/WP3/WP4 jumpers |

| Mounting | DIN Rail or Panel Mount |

| Environmental Tolerance | -20°C to +70°C, 5-95% RH non-condensing |

Real-World Applications

Commonly deployed in power plants and large-scale manufacturing facilities, this module excels in environments requiring rock-solid voltage control for turbine systems. A plant engineer in Houston recently shared how it maintained stable operation during voltage fluctuations in a natural gas power station. Our inventory includes complementary GE modules like VMIVME-7807, IS230SRTDH2A, and IC698CPE010, ensuring seamless integration into existing control frameworks.

Performance Advantages

What sets this module apart is its ruggedized design that survives harsh industrial conditions – I’ve seen units operate flawlessly in steel mills with constant vibration and temperature swings. The jumper-configurable voltage range eliminates the need for multiple SKUs, while GE’s proprietary diagnostics system flags potential issues before failures occur. Redundant power paths ensure uninterrupted operation during maintenance, a feature that saved a Midwest chemical plant $50k in potential downtime last year.

Reviews

There are no reviews yet.