Description

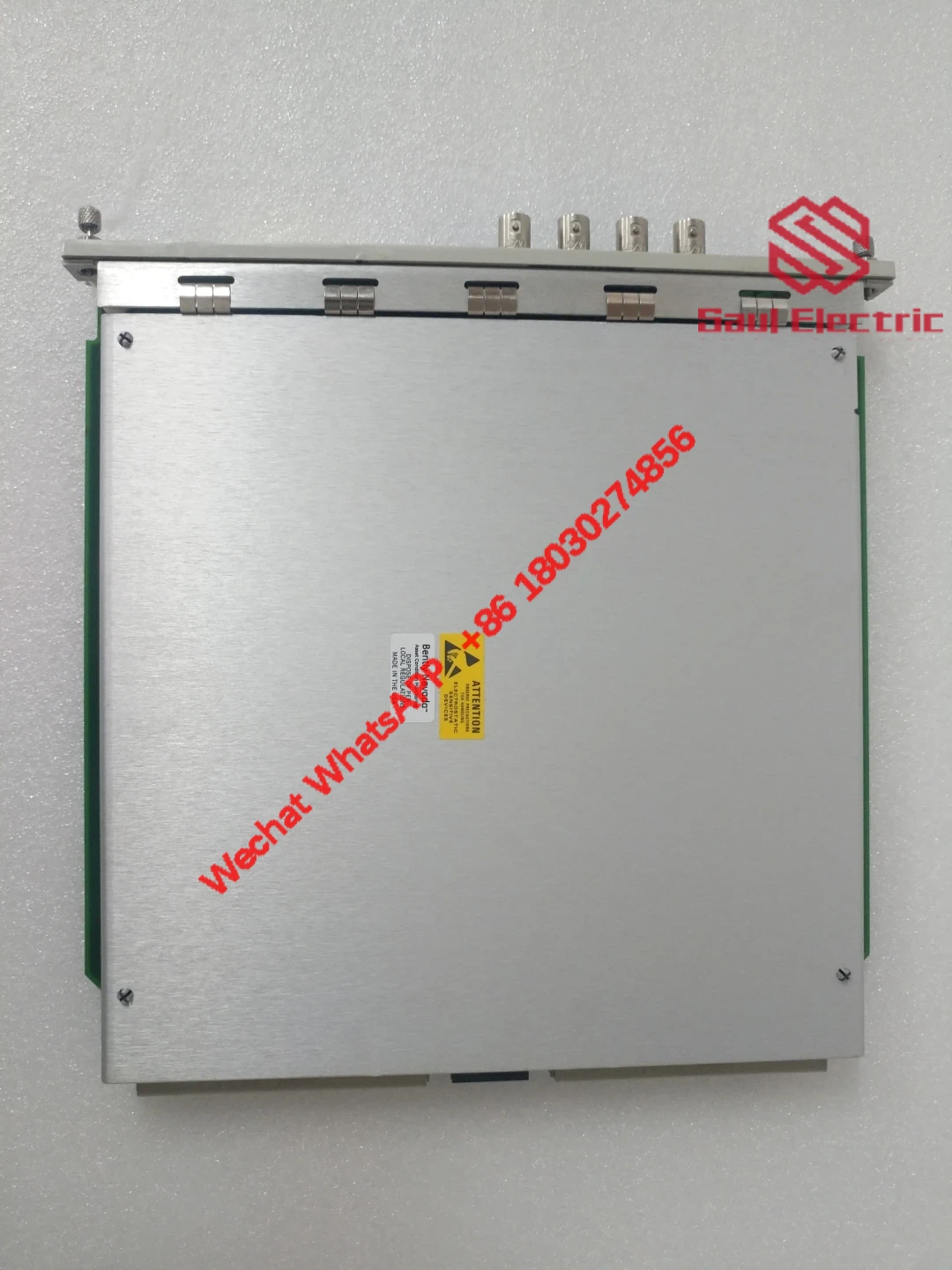

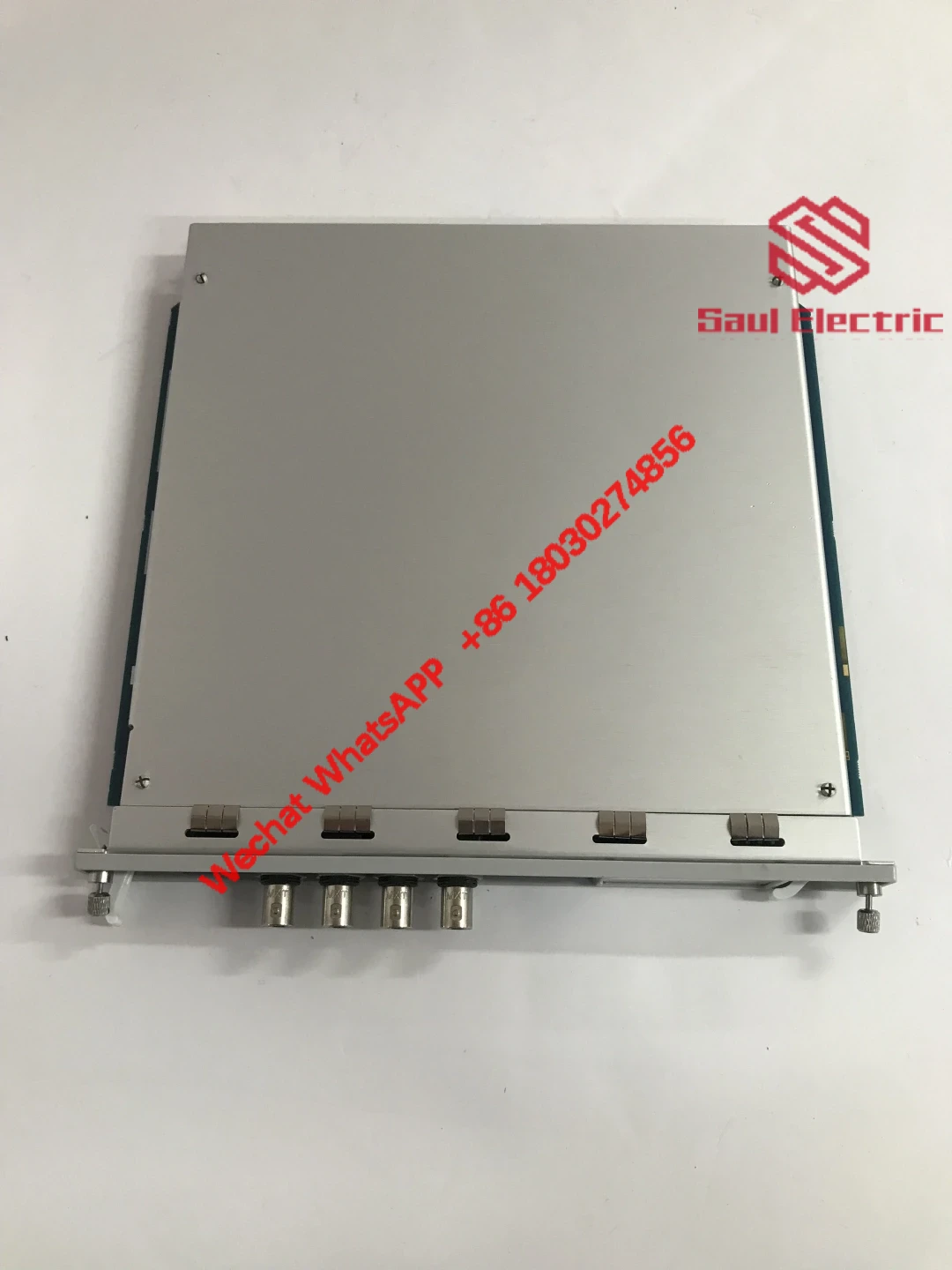

BENTLY 3500-42M 176449-02 Vibration Monitoring Module

This BENTLY 3500-42M module serves as a critical component for machinery protection systems, specializing in continuous vibration monitoring of rotating equipment. Widely used in power plants and oil & gas facilities, it helps prevent catastrophic failures by detecting abnormal vibration patterns in turbines, compressors, and pumps.

| Attribute | Specification |

|---|---|

| Brand | Bently Nevada |

| Model Number | 3500-42M |

| Order Code | 176449-02 |

| Voltage Requirement | 220 V AC |

| Signal Output | 50 kHz analog output |

| Certifications | CE, UL, RoHS |

Designed for integration with Bently’s 3500 system racks, this dual-channel module supports both proximity probe and velocity sensor inputs. Field engineers particularly appreciate its self-diagnostics feature – during a recent offshore platform installation, the module’s built-in test function identified a wiring fault before commissioning, saving 48 man-hours of troubleshooting. The 3500-42M’s modular design works seamlessly with existing 3500/20, 3500/22M, and 3500/44 system racks, making it a preferred choice for retrofit projects.

Technical Advantages

What sets this module apart is its dual-redundant configuration capability – when paired with a 3500/92 power supply module, it achieves SIL-2 compliance for critical applications. The adjustable alarm thresholds (0.1-25 mils pk-pk) allow fine-tuning for specific machinery characteristics, while the 4-20mA output maintains compatibility with legacy DCS systems.

- Self-calibrating circuitry maintains ±0.5% accuracy over 5 years

- Hot-swappable design enables maintenance without system shutdown

- Integrated buffer memory retains 32 event logs with timestamps

- Operating temperature range: -25°C to +70°C

Reviews

There are no reviews yet.