Description

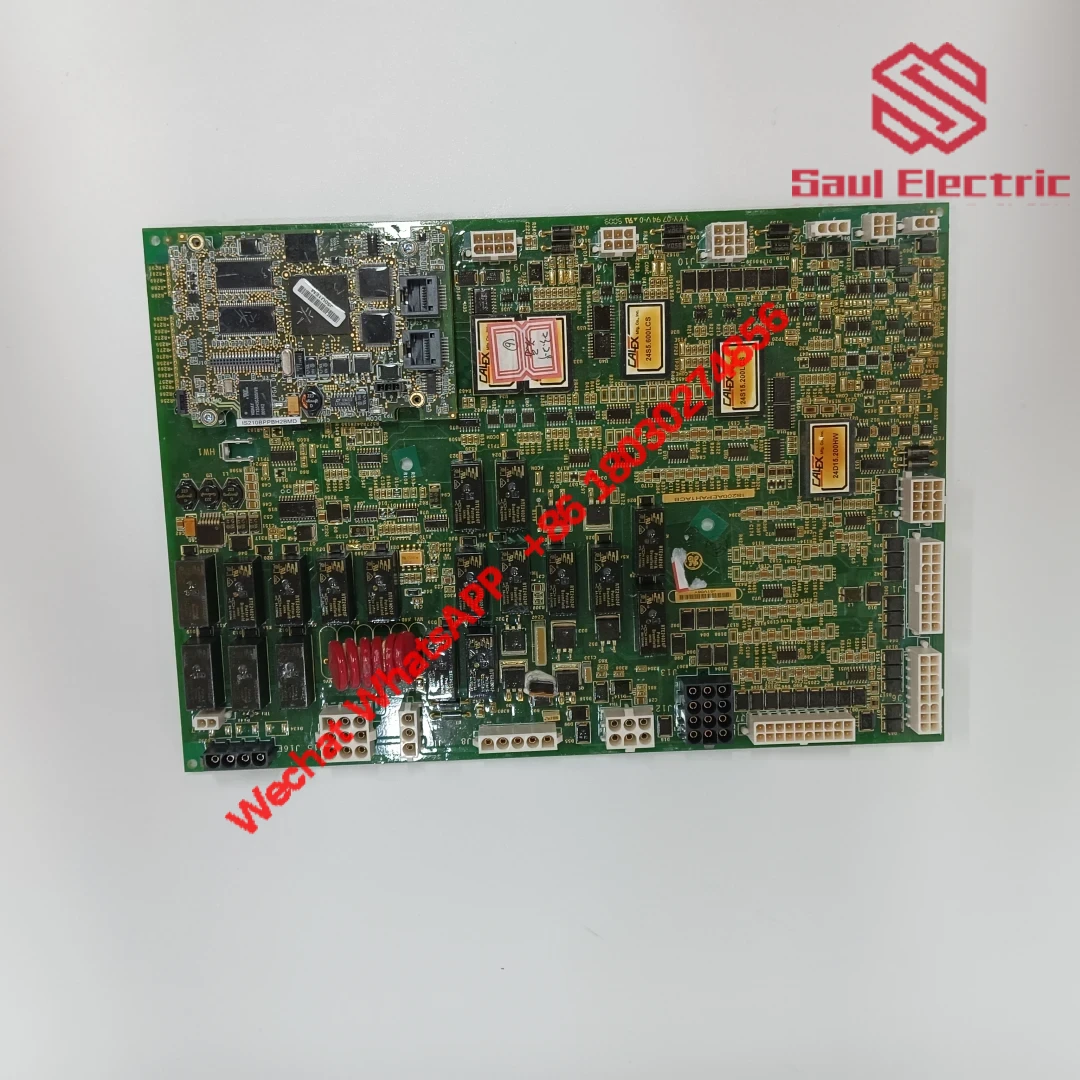

TOSHIBA 9110 High-Performance Industrial Control Module

This TOSHIBA 9110 module serves as a precision automation workhorse for challenging environments. Engineers frequently deploy it in manufacturing lines, energy systems, and process control setups where reliability matters most. Its robust design handles everything from conveyor belt synchronization to HVAC regulation without breaking a sweat.

| Specification | Details |

|---|---|

| Manufacturer | TOSHIBA |

| Model | 9110 |

| Power Requirements | 24 VDC (20.4-28.8 VDC range) |

| Processing | 32-bit RISC CPU |

| Memory | 512 KB Flash / 256 KB RAM |

| I/O Capacity | 16 DI / 16 DO channels |

| Certifications | CE, UL, RoHS |

When we helped a Midwest food processing plant upgrade their automation setup, this module became our go-to solution. Its modular architecture seamlessly integrates with existing SCADA systems while supporting expansion through optional analog modules. Customers particularly appreciate how it handles temperature extremes (-10°C to 60°C operational range) in harsh environments like steel mills or outdoor HVAC installations. Common applications include robotics control, packaging machinery, and conveyor systems where split-second timing matters.

What sets this module apart? The dual communication ports (RS-485 + CANopen) provide flexible networking options while the industrial-grade components withstand electrical noise and vibration. Unlike basic PLCs, its memory capacity handles complex logic sequences without performance drops. The built-in redundancy design ensures continuous operation even during component failures – one customer mentioned how it kept their 24/7 bottling line running during a power fluctuation incident. While Toshiba doesn’t publish exact dimensions, field technicians confirm its compact footprint fits standard 19″ rack enclosures without space issues.

Reviews

There are no reviews yet.