Description

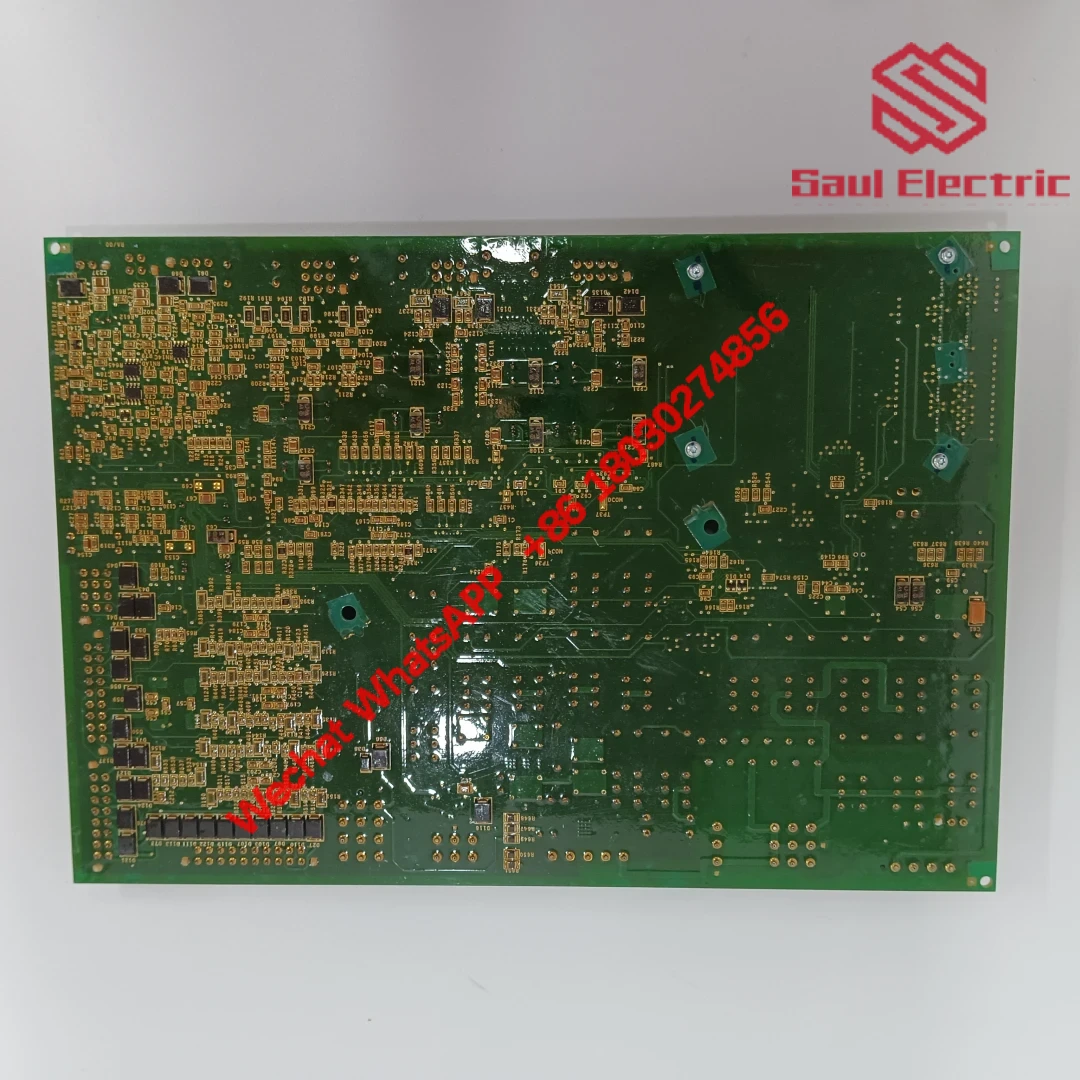

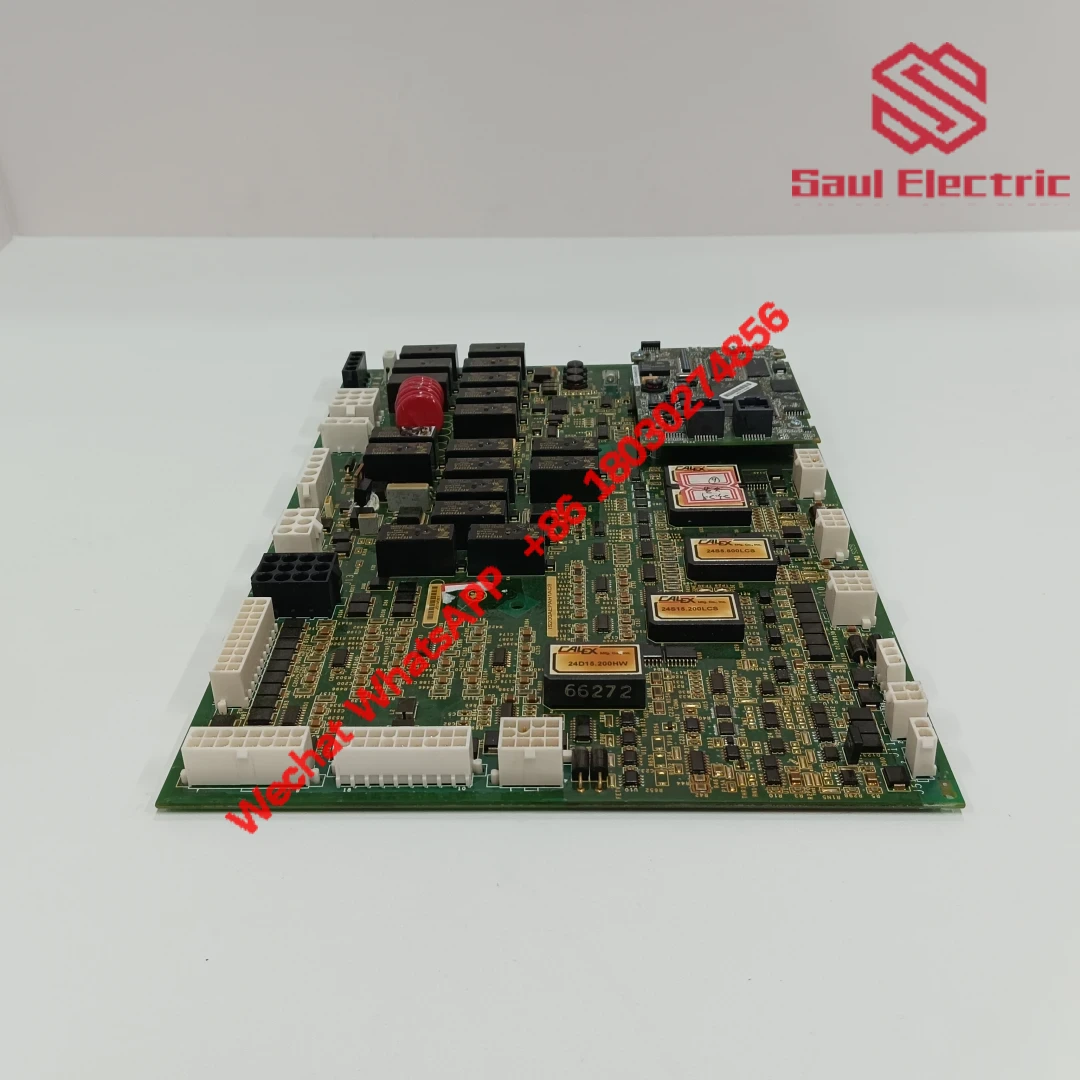

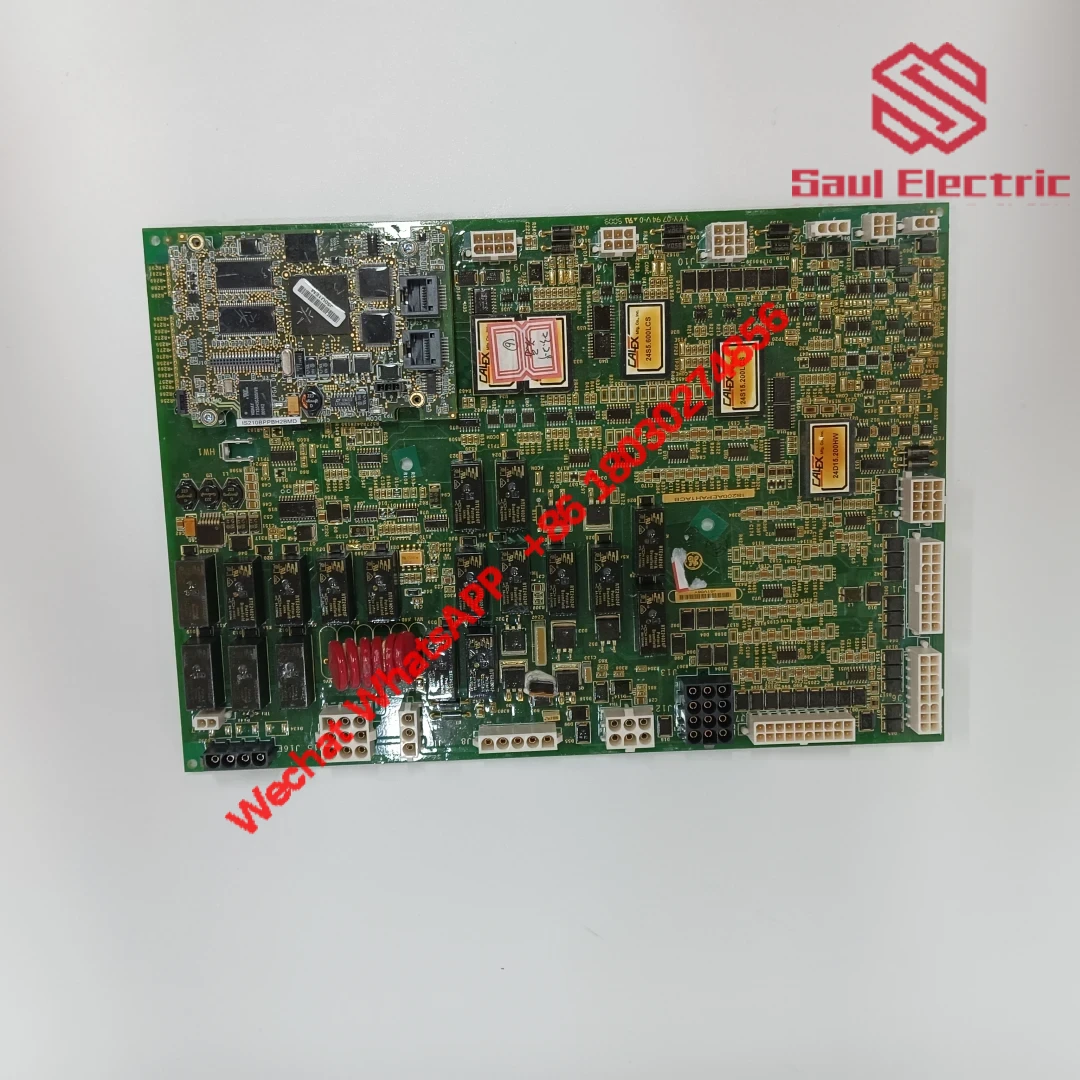

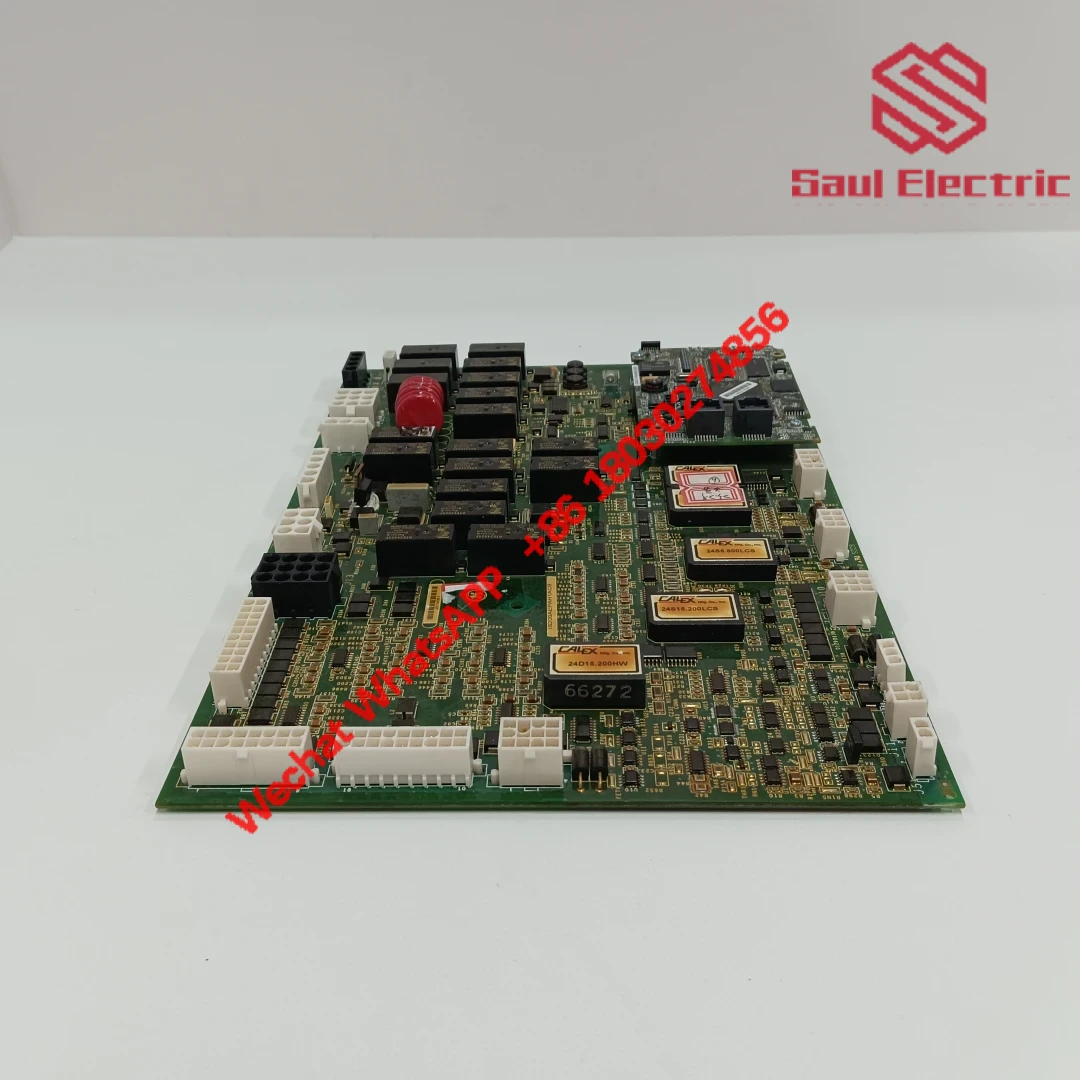

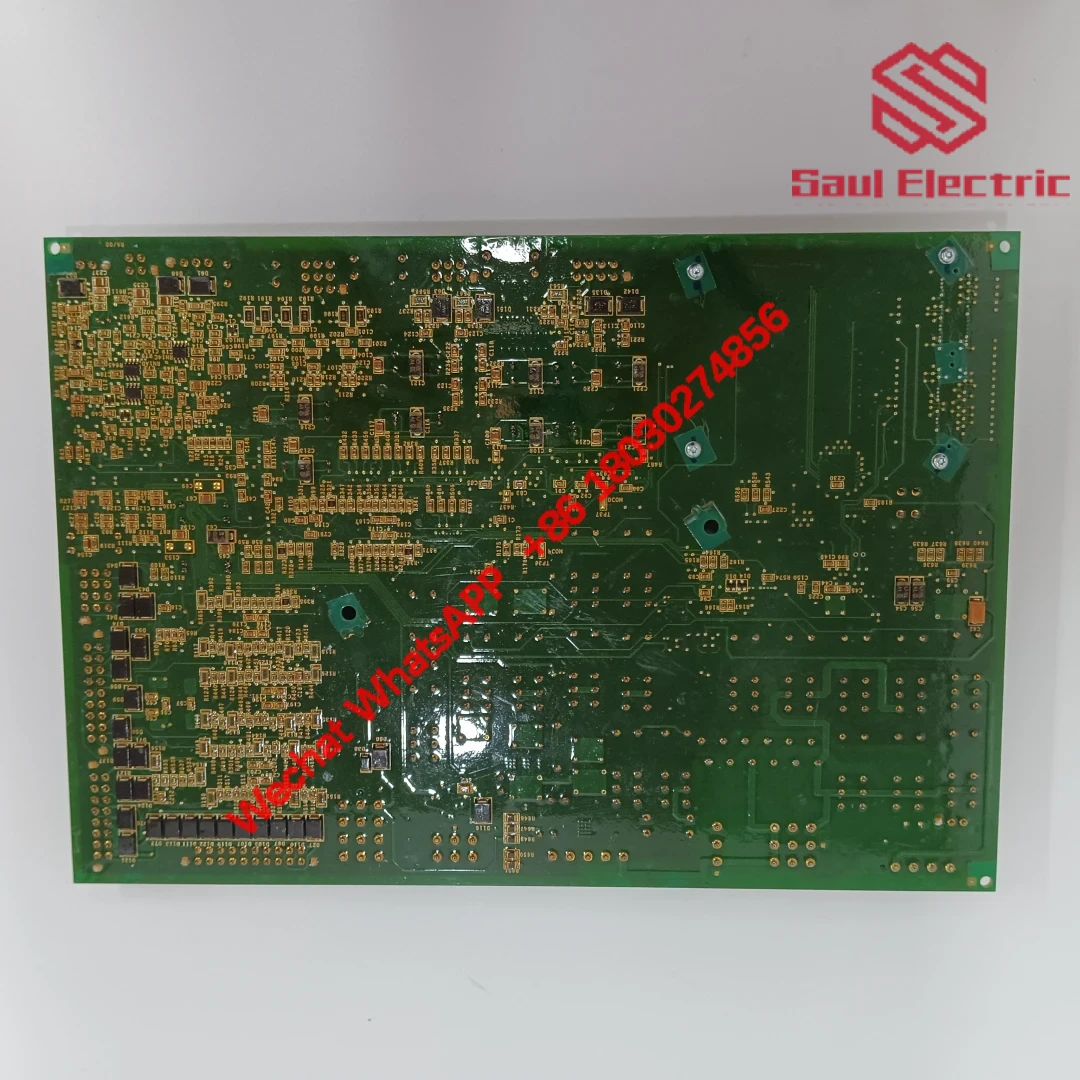

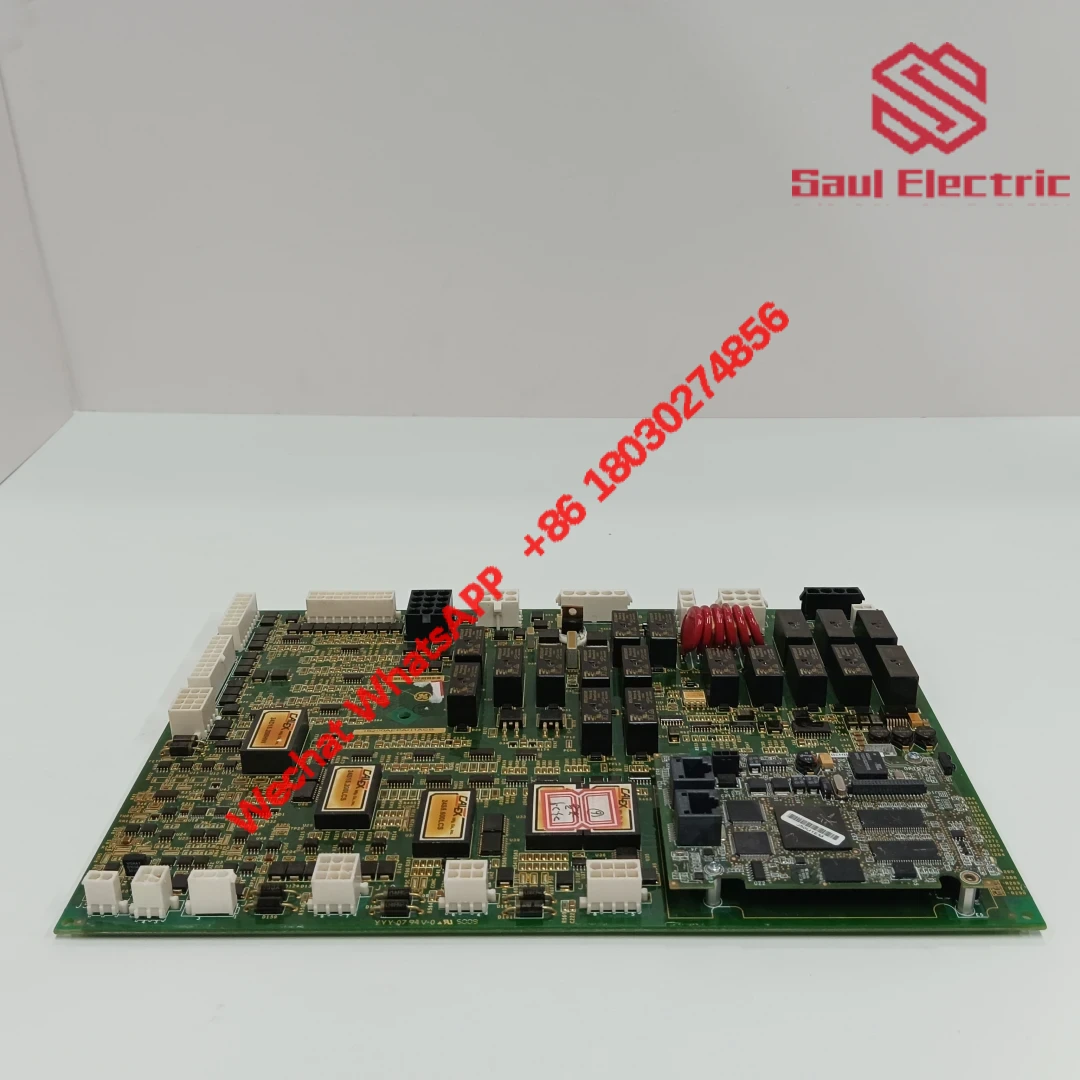

GE IS200AEPAH1ACB+IS210BPPBH2BMD Industrial Control Module

Engineered for critical automation tasks, this dual-module system combines turbine control precision with industrial communication reliability. The IS200AEPAH1ACB handles complex control logic while the IS210BPPBH2BMD manages data exchange, making it ideal for environments where system failures aren’t an option – think gas turbine controls or offshore drilling platforms.

| Brand | Attributes | Dimensions | Weight |

|---|---|---|---|

| GE | TMR/Simplex redundancy, 24V DC operation, -40°C to +70°C tolerance | Standard rack mount (19″) | 1.8 kg (approx) |

Commonly deployed in power generation plants and oil & gas facilities, this module pairs perfectly with GE’s Mark VI Speedtronic systems. We frequently supply these alongside complementary components like the IS200SPTCH2BCD turbine interface module and IS220PPDAH1B communication boards. A refinery in Texas recently upgraded their turbine control system using this module, reporting a 30% reduction in unplanned downtime after implementation.

What makes this setup special? The triple modular redundancy design means if one processor fails, the system keeps running – no shutdowns required. The built-in Ethernet and Profibus interfaces play nicely with legacy DCS systems, which matters when upgrading older plants. One engineer mentioned how the hot-swappable design let them replace a faulty card during peak production without stopping the line. It’s built like a tank too – survived 18 months continuous operation in a desert power plant where temperatures regularly hit 55°C.

Reviews

There are no reviews yet.